Get a callback from our team within 20 minutes during business hours.

Client background

Our client, a leading equipment rental provider in the UK, forms part of the FTSE 100-listed Ashtead Group. With thousands of customers and a catalogue covering everything from tools and plant to specialist equipment, they support major infrastructure and commercial projects nationwide.

The challenge

Processing large, complex hire tenders from multiple clients—each with their own formats and requirements—was eating up valuable time. The finance team in particular was spending hours manually manipulating data instead of focusing on high-value tasks.

The solution

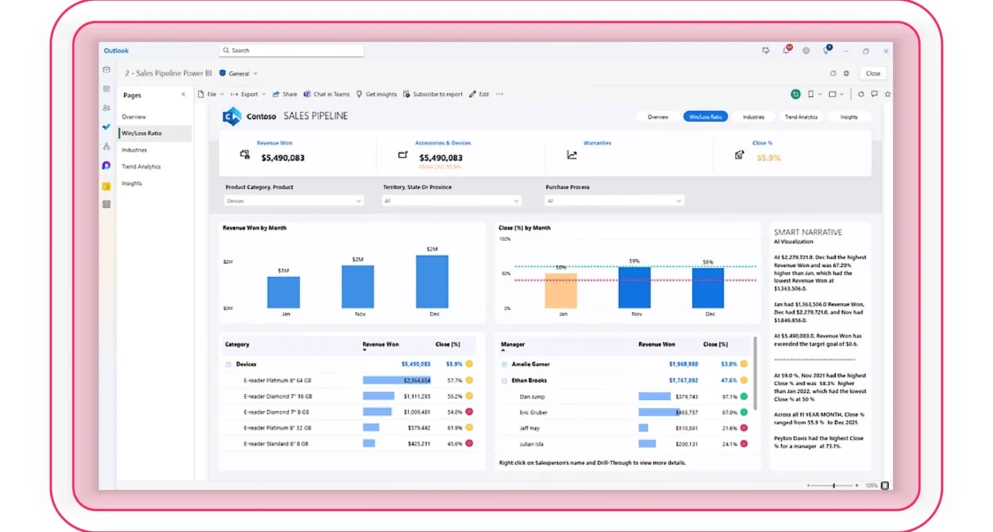

A bespoke digital transformation project that automated key workflows and introduced smarter data analytics and matching capabilities to reduce manual input, improve accuracy, and speed up enquiry handling.

As part of the second-largest equipment rental company in the world, our client deals with thousands of customers across thousands of different projects.

But a huge product catalogue combined with each customer’s unique approach to hire tenders required huge amounts of time and effort. Not only was this stunting efficiency, but it also meant the finance team spent more time on admin than value-add tasks.

A smarter, more automated approach was needed, without asking customers to change how they submitted their data.

The new process delivered immediate improvements for the team, with less time spent on repetitive admin and more consistency across tender responses.

Standardising incoming data meant users no longer had to manually reformat spreadsheets or decipher varied product names. Matching was faster, more accurate, and less reliant on individual knowledge, creating a more scalable and repeatable process.

With an exceptions process and searchable match history built in, the tool continues to improve over time—reducing rework and supporting a more efficient workflow for future tenders.

Client background

A well-established business in the plant hire industry, operating across multiple depots in the UK and Ireland. With a large workforce and a high number of subcontractors, they support projects nationwide.

The challenge

As the business grew, manual processes and legacy systems became a barrier to efficiency. Routine admin tasks were taking too long, data was difficult to access, and errors were creeping in.

The solution

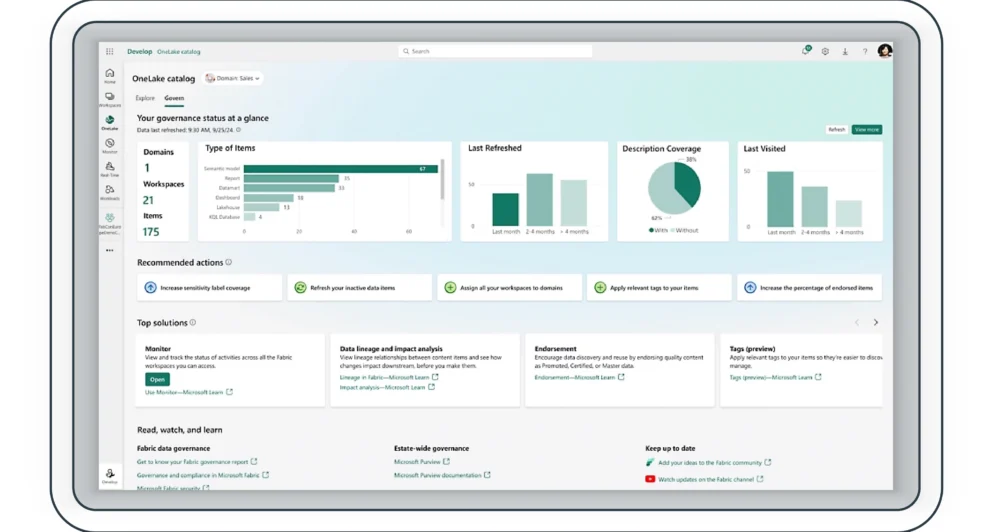

Fabric & Power Platform

Having sustained continued, rapid growth, our client needed to upgrade their internal processes to ensure they could scale effectively. Numerous manual processes and legacy systems were starting to show signs of needing updates and business insights were proving difficult to obtain.

Processes were taking the team too long and human error was becoming a problem, so these inefficiencies needed to be addressed.

The client’s timesheet process relied heavily on manual input. Staff submitted paper forms via photo and email, which were then individually reviewed, verified, and rekeyed into another system, taking up approximately 120 hours of staff time each week and introducing a high risk of error.

Invoice processing presented a similar challenge. Each month, invoices were submitted, and a small internal team spent over 240 hours manually extracting data and entering it into the appropriate systems. This was not only time-consuming but also prone to inconsistencies.

When reviewing each project, we were able to establish savings for each process. It was calculated that 85% efficiency savings could be realised from each project by introducing Power Automate’s AI Builder and Cognitive Services technology.

By setting data markers on each process, the AI tech was able to extract this data at the point it was received into a central mailbox. A trigger was then set into motion and the data was collated in a central database held on SharePoint before automatically uploading into a separate system. Within the process, validation rules were built into the flows to make sure any inaccurate or incomplete entries were rejected and shared back to the team for re-submission.

Through automating a large part of the timesheet reader process and removing the main requirement for manual checking, the client has made a revenue saving of £65,000 per year.

Extracting data from invoices at the point they are received, and sending this data automatically to their existing finance system, has saved the business £32,000 per year.

The combined saving of £97,000 is being allocated within the business to other technology which will further help the client with their ongoing digital evolution.

We will be working on some strategic deployments over the coming months, namely;

Discover more on 5 ways to get the most out of your data.

The Science and Technology Facilities Council (STFC) is the UK government agency committed to pushing the boundaries of research in science and engineering.

By providing vital support to university-based research and ensuring access to cutting-edge scientific facilities, the STFC plays a crucial role in driving innovation.

Collaboration is at the heart of their approach, fostering strong partnerships between academia and industry to ensure that research delivers tangible economic, societal, and international benefits to the UK.

STFC were experiencing inconsistencies across different sites resulting in inefficiencies and challenges in project tracking. To address this, they partnered with Bespoke to streamline their project management processes by migrating them onto the Power Platform.

The solution was designed to standardise and enhance their ability to manage projects effectively across all stages, from the initial pipeline to final completion.

Bespoke developed a comprehensive solution featuring four interconnected Power Apps, reporting dashboards, and Power Automate flows.

Power Apps Development: Pipeline Tracking, Project Request, Project Management, and Cost Tracking enable seamless data transfer and automation.

Support: In addition to developing the solution, Bespoke provided expert advice and hands-on support to ensure the system was used effectively.

Follow-up workshops: Bespoke conducted follow-up workshops to secure the Power Platform environment with appropriate guardrails, ensuring the solution met all of STFC’s needs efficiently and securely.

“We have partnered with Bespoke to not only develop a new system but also to establish a comprehensive process for our internal Project Management Team. At Bespoke’s recommendation, we created three interconnected applications which resulted in a seamless and efficient workflow for our staff and internal customers.”

![UKRI_STF_Council_White[94]](https://www.bespoke.xyz/wp-content/uploads/2024/09/UKRI_STF_Council_White94.png)

Adrian Mroczkowski – Head of Systems and Data Management

Migration and Streamlining: The implementation of the new solution has allowed STFC to successfully migrate all live projects onto the system, significantly streamlining their project management processes. They are now leveraging the Project Request app to manage new project requirements and populating the pipeline tracker to better predict and plan for future resource needs.

Integration and Enhancement: This successful integration has led STFC to engage Bespoke further to enhance the solution by exploring additional features for resource tracking and planning. The goal is to ensure continuous improvement and operational efficiency, enabling STFC to maintain a consistent and transparent approach to project management across all areas.